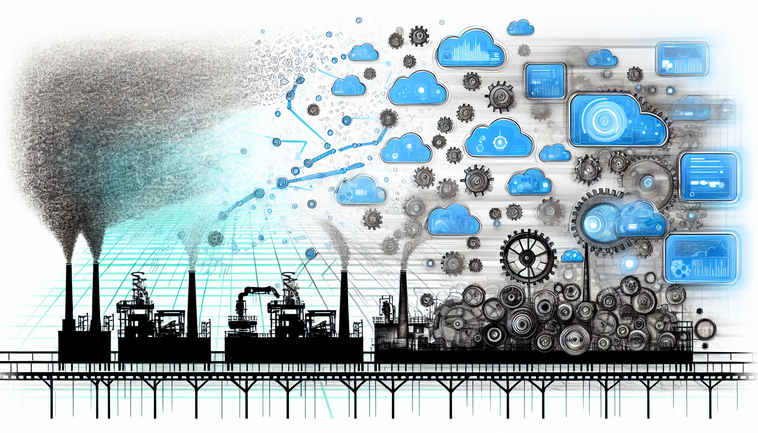

Industrial operations are no longer driven solely by steel and steam; today’s factories pulse with data streams, smart sensors, and advanced analytics. This new era marks a decisive leap in how businesses design, produce, and deliver goods, blending physical processes with digital intelligence to unlock unprecedented productivity.

At the heart of this revolution lies the Internet of Things. By embedding connected devices in machinery and workstations, companies gain real-time visibility into performance metrics, supply chain movements, and energy consumption. This granular insight helps leaders pinpoint inefficiencies and seize new revenue opportunities faster than ever before.

Artificial intelligence amplifies the impact of raw data by revealing patterns and forecasting outcomes. Predictive maintenance platforms, for example, flag equipment risks before they become costly breakdowns. Beyond firefighting, AI-driven quality inspection systems minimize defects and elevate product consistency, yielding both financial savings and stronger brand reputation.

Meanwhile, smart robotics are evolving from rigid assembly-line arms into agile collaborators. With machine vision and adaptive control algorithms, today’s robots work side by side with human colleagues, taking on repetitive or hazardous tasks and freeing people to tackle creative problem-solving and process optimization.

Cloud and edge computing form the digital backbone of Industry 4.0. While cloud platforms offer scalable storage and powerful analytics, edge nodes deliver low-latency decision-making right on the factory floor. The synergy between centralized data lakes and local processing units ensures seamless coordination and rapid response to changing conditions.

However, technology alone cannot guarantee a successful transformation. Organizations must nurture a culture of continuous learning, equipping employees with new skills in data literacy, automation oversight, and cybersecurity. Change management, transparent communication, and cross-functional collaboration become critical for embedding digital practices into daily workflows.

In conclusion, turning physical factories into intelligent ecosystems demands a balanced approach—combining cutting-edge technologies with strategic leadership and a people-centric mindset. By embracing IoT connectivity, AI insights, collaborative robotics, and flexible computing architectures, industrial enterprises can redefine competitiveness for the digital age. The journey may be complex, but the promise of safer, smarter, and more sustainable operations makes it an imperative for anyone aiming to lead in tomorrow’s marketplace.